Wind power drives SA’s future of sustainable energy

This article has been supplied.

By: Richard Reid - Regional Director at Concord Cranes

When people talk about renewable energy, solar power usually gets all the attention. However, wind power, with its simple design, holds major potential and is quietly becoming one of South Africa’s best hopes for a cleaner, more reliable energy future.

According to a report by the South African Wind Energy Association (SAWEA), wind energy is increasingly turning into a leading driver of South Africa’s transition to a future built on renewable energy. The country has world-class wind resources, especially along its extensive 3,000 km coastline, particularly in the Eastern and Western Cape.

As of March 2025, SAWEA estimates that over 3.5 GW (gigawatts) out of 63,4 GW of installed capacity is generated from the 37 wind power plants currently operating in the country. These wind farms are estimated to contribute over 46,480 GWh (gigawatt hours) annually.

“Although solar power is more widely adopted – especially at the residential level – wind farms are purely mechanical and don’t rely on complex chemical processes,” says Reid. “But the logistics and planning behind getting a wind farm operational are highly complex.”

With the Integrated Resource Plan (IRP 2024) set to be released this year, wind energy is projected to contribute between 69 and 76 GW of new capacity by 2050. “This presents significant opportunities for investment, industrialisation and job creation,” Reid adds.

Infrastructure to deliver

While wind power generation uses a simpler mechanical process, the components are large and heavy, requiring precise logistics management to enable efficient rollout of wind farms.

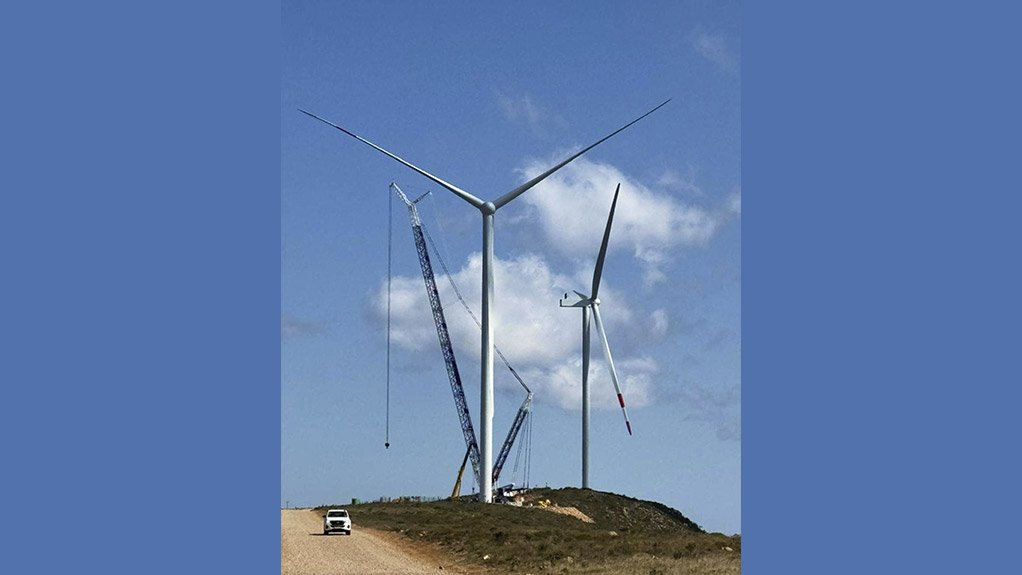

In the ‘wind-rich’ landscapes of the Eastern and Western Cape, Concord Cranes is helping power the country’s renewable energy future, one turbine at a time.

“Since June 2025, we started supporting African Clean Energy Developments in the construction of a 144 MW wind farm. Our 260t crawler crane, operated by a team of 12 to 20 experts over an 11-month project, off-loads equipment from vessels in the laydown area at Port of Coega in Gqeberha, and then reloads it on demand for delivery to the site in Murraysburg,” says Reid.

While this may sound straightforward, he emphasises the sheer scale of the work. “The planning and detail required to get these projects completed is enormous, and the financial commitment is equally significant.”

In broad terms there are three tasks that need to be undertaken, and the requirements for each vary quite considerably.

Phase 1 - discharging the vessel

The first step focuses on logistics in the port: off-loading all the turbine components, such as blades, tower sections and nacelles, into the port laydown area for storage. “This 24-hour round-the-clock operation requires cranes, specialised vehicles and rigging crews and can take up to seven days,” Reid explains.

Once this is completed, re-loading the components – some weighing up to 130 tonnes, 90 metres long and 6 metres wide – are re-loaded onto specialised vehicles for transport to site. Detailed route surveys identify obstacles along the way, and all the necessary permits and police escorts must be arranged well in advance.

“A delivery of a set of three blades will require a convoy of up to 10 vehicles, excluding the delivery trucks themselves. By car, the drive from Port of Coega to Murraysburg takes about four hours, but with these oversized loads and the complexity of the operation, a layover is often required,” he says.

Phase 2 – building the turbines

Once components arrive on site, assembly cranes off-load them in a detailed logistics operation. “The turbines themselves can reach heights of 120m,” says Reid. “Positioning the nacelle, containing the drive train and weighing between 80 to 120 tonnes, and then attaching the rotor and blades at heights up to 130 metres must be done in near wind-free conditions, often in the freezing early hours.”

Here, the contractor must adhere to strict safety standards using cranes with between 800 and 1,000 tonnes, as well as a variety of support and tailing cranes.

Phase 3 - maintenance afterwards

The third operation is repairs and maintenance of existing turbines. “This involves getting spare components to site, providing cranes, riggers and the removal of damaged parts,” he says.

As with the previous phases, safety and compliance remain central.

“Every employee or subcontractor must have valid medical certificates, working at height certificates and certificates of competence,” Reid adds. “Then there’s letters of appointment, labour market information, letters of good standing, professional driving permits and confirmation of public liability cover. Plus, every contract must include a detailed risk assessment, method statement, safe operating procedure and lifting plan.”

While wind farming itself is a relatively simple and scalable way of producing electricity, setting it up is an intricate logistical ballet, with countless moving parts.

“Each of these must be managed carefully, with continuous improvements in processes to ensure that South Africa can take full advantage of its abundant wind resources and power the country’s economic growth and a sustainable future for the next generation,” says Reid.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation